Commercial Gate Grounding + Electrical Isolution Systems

Grounded in Safety.

Continuous gate grounding and non-conductive isolation kits engineered

for fault-current performance, personnel protection, and utility-grade compliance.

Sustainable System

Every VANQUISH grouding and isolation systems are manufactured from proven materials — 316 stainless steel, silicon bronze, copper-clad conductors, and reinforced fiberglass — engineered to withstand fault currents, corrosion, vibration, and continuous mechanical movement with minimal maintenance.

Trusted Performance

Our grounding and isolation systems meet or exceed ASTM F855 Grade 3, IEEE 837, and NETA ATS 7.13 testing requirements — ensuring low-impedance performance, fault-current integrity, continuous grounding through motion, and long-term electrical stability across mission-critical installations.

Simplified Integration

Each kit is engineered for real-world compatibility — retrofitting to common gate systems and integrating seamlessly across metallic and non-conductive fence lines. Pre-engineered components reduce field adjustments and installation time while maintaining safety and compliance.

Technical Systems that Protect You

VANQUISH accessory systems deliver purpose-built, utility-grade solutions for continuous grounding and electrical isolation across dynamic and static installations at mission-critical sites. Each kit is engineered to:

Maintain a safe, low-impedance bond through motion in moving gate systems

Separate independently grounded fence lines and transition zones using non-conductive fiberglass assemblies

Utilize high-performance materials—advanced metals, copper-clad conductors, and reinforced composites

Provide stable, long-lasting, reliable performance under real-world operating and fault-current conditions

Meet all applicable ASTM and IEEE standards

Align with NETA testing practices to ensure safety, compliance, and confidence across every installation

Engineered to Perform in Every Condition

-

Continuous Grounding

Trolley Ground Kits maintain a continuous, low-impedance path to ground during gate movement. A tensioned 19/9 copper-clad conductor travels with the gate frame, while the trolley ground connector — using v-groove sheaves and conductive brushes — maintains constant contact, preserving bonding integrity during both normal operation and fault conditions in utility and industrial environments.

-

Electrical Isolation

ISO Kits create engineered non-conductive barriers using fiberglass dielectric panels that separate independently grounded fence systems and transition zones. This prevents dangerous potential transfer from energized to non-energized sections of fence and enhances personnel safety at substation perimeters.

-

Universal Compatibility

Both kits are built for real-world utility environments — retrofitting easily to common gate systems and integrating across metallic and non-conductive fence lines, including VANQUISH systems. All grounding components meet applicable ASTM and IEEE 837 requirements for utility-grade integration.

-

Simplified Installation

Pre-engineered hardware, shared-footing options, and standard grounding connectors reduce field adjustments and eliminate the need for custom fabrication. Mounting and tensioning assemblies are engineered for fast, accurate installation, ensuring reliable grounding performance with minimal site adjustment.

-

Proven Compliance

Validated through ASTM F855 Grade 3 short-circuit requirements and NETA ATS 7.13 impedance testing standards. Engineered for dependable operation under real-world fault events — including a maximum use current of 37 kA at 15 cycles.

-

Trusted by the Industry

Demonstrated performance across utility installations nationwide, with systems deployed by Duke Energy, Entergy, LCRA, AEP, and major EPC and utility contractors nationwide. Each kit is engineered for long-term durability, consistent grounding behavior, and dependable protection in mission-critical environments.

Grounding & Isolation System Options

Select the system designed for your site conditions, grounding requirements, and safety standards.

Continuous Grounding Through Gate Motion

Maintains a continuous, low-impedance path to ground during cantilever and rolling gate movement. Designed to preserve bonding integrity under both normal operation and fault-current conditions.

Best for sites requiring continuous grounding of moving cantilever and rolling gates.

Trolly Ground

Electrical Isolation Between Independent Grounding Systems

Creates non-conductive separation using fiberglass dielectric assemblies to prevent dangerous potential transfer between independently grounded fence lines, gates, and metallic systems.

Best for sites requiring separation between independent grounding grids.

Isolation (ISO)

OUR WORKING PROCESS:

From Evaluation to Installation Support

Analyze

We evaluate grounding and isolation requirements based on utility standards, gate style, conductor sizing, and site-specific grid conditions to ensure safe, continuous bonding or proper dielectric separation.

Engineer

Each system is designed to meet ASTM F855 Grade 3, IEEE 837, and NETA ATS 7.13 testing practices, using precision-built components such as copper-clad conductors, v-groove sheaves, dielectric fiberglass panels, and stainless hardware.

Validate

Our kits are tested for low-impedance continuity, mechanical reliability during gate movement, fault-current behavior, and long-term durability in real-world environments before deployment in the field.

Support

VANQUISH provides for-construction drawings, installation sequencing, hardware guidance, and responsive technical support — ensuring correct alignment, tensioning, and integration during installation.

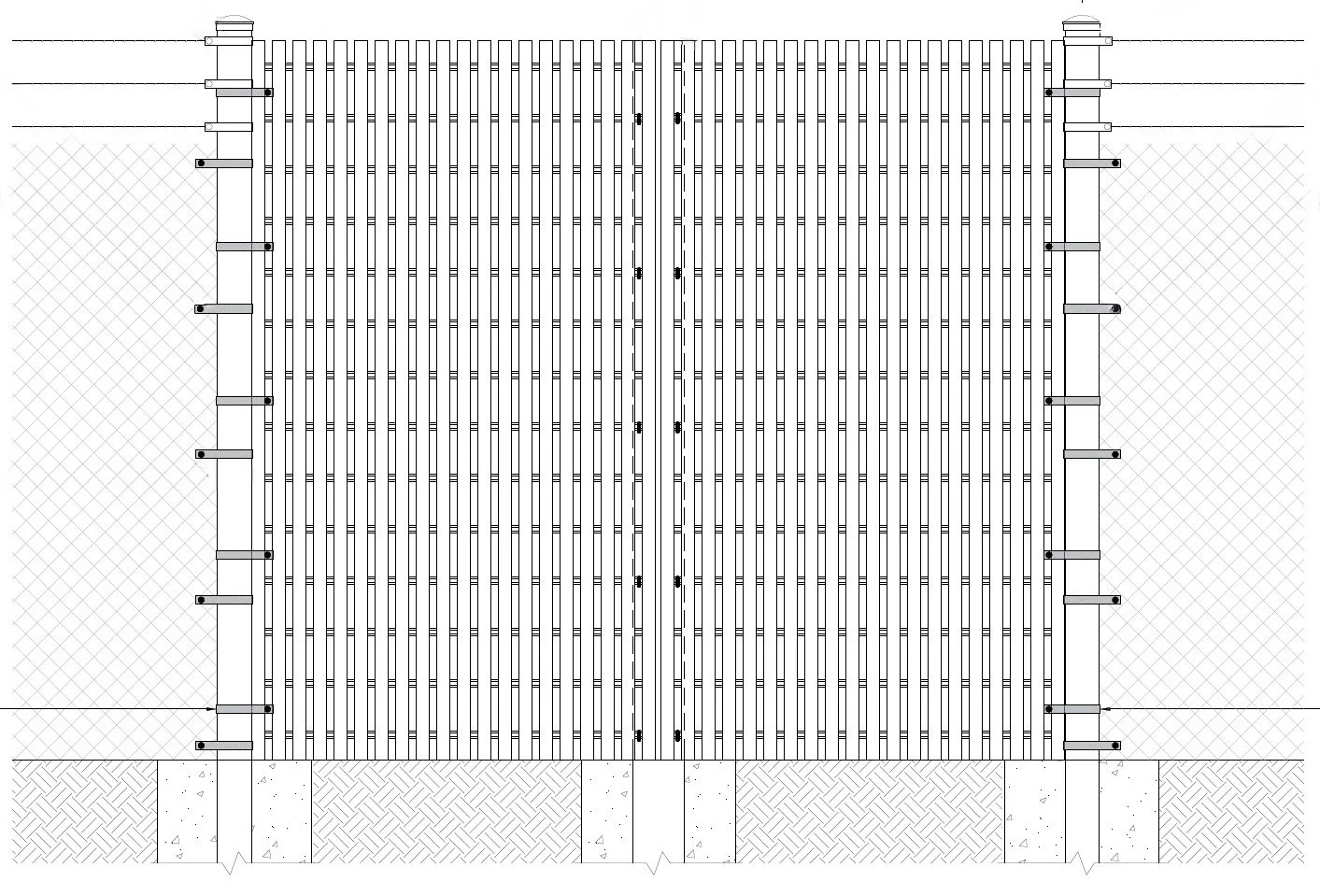

TYPICAL 8FT ASSEMBLY ELEVATION

ISOLATION KIT

Some FAQs

In mission-critical environments, the details matter. These FAQs address the questions we’re asked on every utility and infrastructure project.

-

Both systems are engineered for utility-grade performance. The Trolley Ground Kit meets ASTM F855 Grade 3 short-circuit requirements, IEEE 837 grounding component standards and aligns with NETA ATS 7.13 testing practices. ISO Kits are built from reinforced dielectric fiberglass panels designed to meet structural and performance requirements across utility applications.

-

A tensioned 19/9 copper-clad conductor is pulled across the gate frame and bonded to the uprights. A trolley ground connector with v-groove sheaves and conductive brushes remains in constant contact as the gate opens and closes. A braided stainless strap and grounding clamps then carry continuity back to the station grounding grid.

-

The kit includes 19/9 copper-clad wire as the standard grounding conductor, but utilities may choose their own wire. The system accepts conductors from 1/0 up to 300 kcmil, allowing compatibility with most utility grounding specifications.